CONVENTIONAL NON-DESTRUCTIVE TESTING

Conventional Nondestructive Testing (NDT) describes a process in which welds, materials or equipment can be examined for various types of discontinuities such as cracks, weld discontinuities, corrosion, or wear that does not require the destruction of the component being tested.

Non-destructive testing has become a widely used solution for numerous types of industrial project in the manufacturing, construction, plant operation and other engineering sectors. There are many different NDT methods available, each of which has both advantages and disadvantages. Our NDT team provides qualified inspectors with the capability to choose the right method to solve the inspection or testing challenge that any industrial project might face. As a result, you can be sure of both safe operation and improved quality while reducing overall cost. We perform shop or field inspections wherever required to any codes, standards or customer specification.

Ultrasonic Inspection

Ultrasonic Weld Scan In Ultrasonic Testing (UT), very short ultrasonic pulse –waves…

Learn more

Ultrasonic Thickness Gauging

UTG is a method of performing non-destructive gauging (measurement) of the local…

Learn more

Magnetic Particle Testing

MPI is a NDT technique for detecting surface and subsurface discontinuity in…

Learn more

Liquid Penetrant Testing

LPI is widely applied as low cost inspection method used to locate…

Learn more

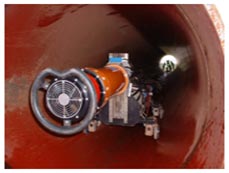

Radiographic Testing

Radiographic inspection is based on the exposure by Either an X-ray machine…

Learn more

Eddy Current Testing

What Is Eddy Current Testing? Eddy current testing is an advanced Non…

Learn more

Helium Leak Testing (LT)

Helium Leak testing is a highly precise means of leak detection and…

Learn more

Positive Material Identification (PMI)

PMI, the analysis of a metallic alloy to establish composition by reading…

Learn more

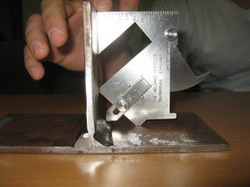

Ferrite Testing

Austenitic, Duplex, Super-duplex stainless steels require adequate proportion of ferrite in the…

Learn more

Heat Treatment Services (Local & Stress Relieve)

Heat Treatment Services Aqualis offers a full range of heat treatment services…

Learn more